The FPC Clean Air Act has been developed for use in a large variety of baking and

cooking processes. The system provides the perfect combination of vapor extraction

and cleaning, and has many food industry applications.

The FPC Clean Air Act is able to reduce vapor pollution from the emissions up to

68 percent. The unit is equipped with a variable ventilator that pulls out the vapors

released in the cooking process, so that the working area can be kept free from any

irritating and greasy air.

The FPC Clean Air Optimizer AC is a filter based on activated carbon. Activated carbon is a harmless carbonaceous product. An active carbon treatment is based on the phenomenon that is called adsorption. Adsorption will make sure that the molecules of a liquid or gas are contained in the surface of a solid substance. Activated carbon has a very large internal surface, which makes it very suitable for adsorption. The FPC Clean Air Optimizer AC is used in combination with the FPC Clean Air Act. This is the perfect combination to exhaust, process, and clean fumes. By doing this, the odour emissions are decreased by more than 90%, in some cases even by 100% (DIN EN 13725 / 15259).

The FPC Clean Air Optimizer ES removes organic material and carbon and/or hydrogen bonds in an eco-friendly and energy efficient way. The machine has an air purification technology that offers a unique after-treatment based on an electrochemical high voltage catalyst. This is also called plasma technology or cold plasma. Discharges are taking place all the time, due to the high voltage applied to the plasma electrodes. As a result, free radicals and other very reactive substances can be created. These will react right away with airborne contaminants. The plasma technology will make sure that these substances dissolve into the basic ingredients, such as carbon dioxide and water (vapour).

The FPC Clean Air Optimizer ES is used in combination with the FPC Clean Air Act, and the FPC Clean Air Optimizer AS. Together, these three machines will make sure that the odour emissions are reduced by over 98% (DIN EN 13725 / 15259).

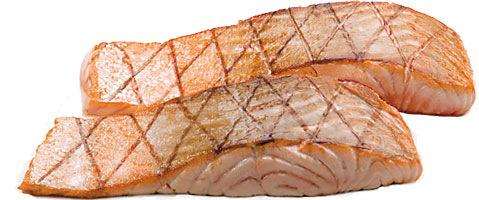

The FPC Food Styler, a revolutionary development in the field of grill-marking in the food

industrie. The FPC Food Styler can create lines, squares and even logos on a wide range

of products.

The contact-free application means that the product is not pressed, so that loss of

moisture is kept to a minimum. The variable settings allows lines and logos to be applied

to the product. The FPC Food Styler can be used as a stand-alone unit or integrated into

a production line.

The system prevents smoke and odours in the processing area.

For more information, visit:

www.foodprocessingconcepts.com

Brochure Clean Air Act

Brochure Optimizer

Brochure Food Styler